An ongoing programme of investment by UK-based Universal Flexible Packaging has seen the company install a further three Ishida DACS-W checkweighers at its factory in Leicester.

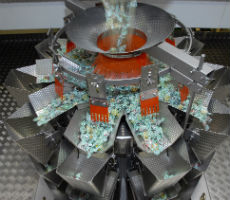

According to the leading flexible packaging supplier and contract packer, the company’s complement of five Ishida mulithead weighers and 12 checkweighers together ensure UFP’s “commitment to quality and service are consistently maintained”.

A key requirement for the new checkweighers was that the machines are able to meet the latest specifications of the UK supermarkets, and Ishida Europe has also upgraded most of the existing models at UFP to include such capabilities.

The majority of the installed checkweighers now include separate reject bins for metal contaminants and incorrect weights, internal alarms for rejects and a coloured beacon to distinguish different problems.

“As a contract packer, we have to continually prove ourselves to our customers,” says UFP chief executive Tinku Durrani.

“This means we do not compromise on our equipment and generally over-specify in order to ensure it can meet our demands both now and in the future.”