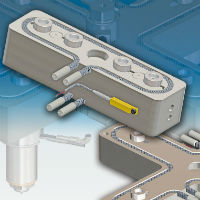

Machinery manufacturer Hasco has launched a “completely revised” H4000/ hot runner concept, said to offer a “very wide range” of layout options despite the different standardised exterior dimensions of manifold blocks.

According to the injection moulding specialist, hole distances for the nozzles can be freely selected within the pre-defined limits, and Hasco also tailors the flow channel cross-sections in the manifolds to the application in question.

“The H4000/ manifold concept is combined with the nozzle series in Hasco’s current nozzle range to provide high-quality hot runner systems that meet the most stringent of requirements for injection moulding production,” the company says.

Existing Hasco turn plugs are employed for the melt channel deflections and as plugs on the manifold bars.

This is said to guarantee a leak-free manifold and optimum passage of the melt through the deflection, while ensuring that the molten polymer is subject to only minimal shear.

The H4000/ manifold concept takes in a series of manifold geometries: simple deflector manifolds are supplied for nozzle spacings from 35mm to 440mm.

Naturally balanced manifolds for 2 or 4 nozzles arranged in a row can also be supplied with a maximum distance of 440mm between the outside nozzles.

The cross-shaped manifolds are designed for a symmetrical nozzle configuration on a square, with a maximum distance of 315mm possible for the nozzle spacing.

“Hot runner systems based on the new, standardised manifold concept H4000/ offer an outstanding price to performance ratio,” Hasco says.

“They are also the answer to tightly scheduled mould projects, since they can be supplied within just a few working days.”