Walki Group has developed Walki-4E, a new technology for producing RFID antennas using a dry process and paper as the substrate – the first real alternative to the wet, chemical based process of etching.

The technical laminates producer says it will this year begin mass production of the first product to be launched using Walki-4E technology – Walki-Pantenna, a UHF RFID antenna.

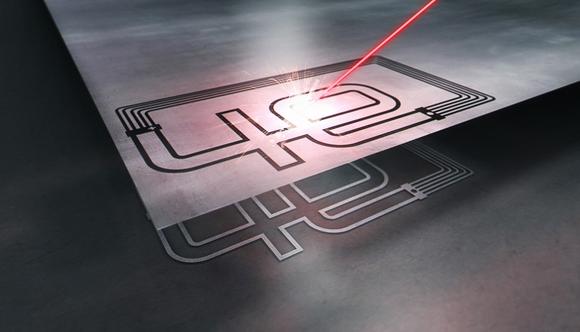

The Walki-4E process involves a special laminate of aluminium and paper substrate, where the aluminium foil is cut in patterns using a laser, and the precision of the laser cutting of the patterns allows for smaller chips, greater repeatability in the production process and higher accuracy of the antenna.

“We think that Walki-4E technology is the first feasible alternative to etching and that it will bring new dimensions of cost efficiency and sustainability to the industry,” says Sami Liponkoski, business line manager at Walki.

The four E’s of Walki-4E stand for ‘efficiency, exactness, economy and ecology’. Compared with etching, the company says the technology eliminates a whole step from the tag production process or from the converter’s process.

“Since paper is used as a substrate, the RFID manufacturers can leave out the insertion of the PET inlay into paper, a necessary step when the antenna has been produced by etching,” says Liponkoski.

“Moreover, the computer to antenna production method speeds up design and development, an advantage especially when it comes to producing short series, involving a fewer number of antennas.”

The absence of liquid chemicals also means that RFID manufacturers can offer a 100% recyclable product, in instances where metal detectors can separate the aluminium.

The Walki-4E technology can be used for any production of flexible circuits boards, ranging from RFID antennas to boards for radiators and flexible displays.

“Our vision is that the antenna production eventually will be completely digital,” says Liponkoski.

“Laser cutting can speed up the production process by ten times, and taking into account the development that laser technology undergoes every year, the possibilities of producing flexible circuit boards with lasers are almost limitless.

“There is a lot of interest in our product and we strongly believe it has the capacity to change the industry.”

The new Walki-4E laser-based technology for dry production of RFID